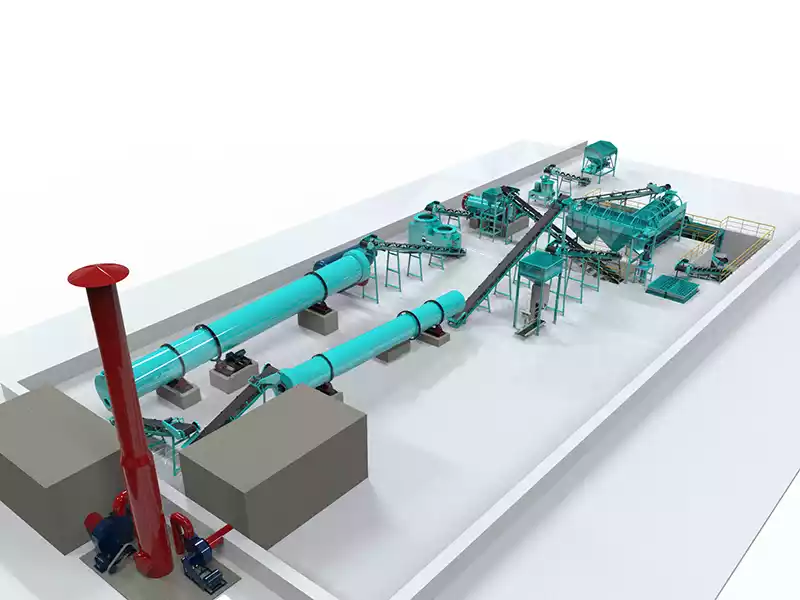

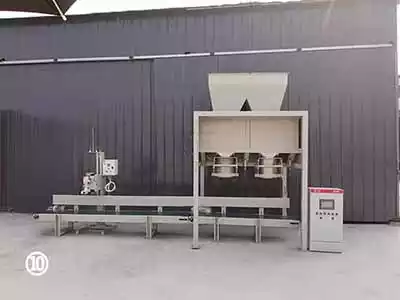

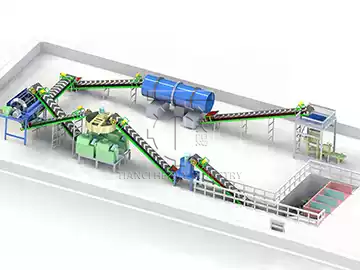

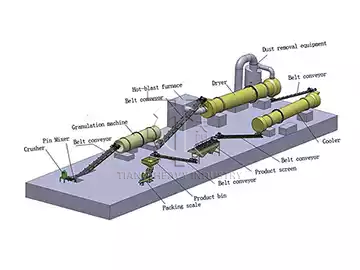

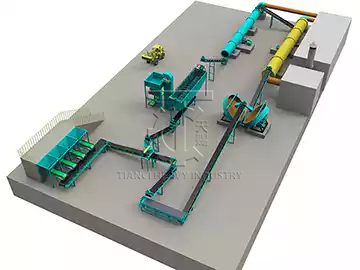

Organic fertilizer Production Line

Usage: Used in the manufacture of organic fertilizer granules

Production capacity: 1-200000tons per year

Raw materials: Chicken Manure, cow dung, animal waste and so on.

Granular Shape: Round shape

Applicable materials: Cattle manure, chicken manure, poultry manure, grass ash, lignite, straw, bean cakes, etc.