Flat die granulator fertilizer production Line

Usage: The production of organic fertilizer pellets

Production capacity: 1-20t/h

Raw materials: Manure compost, sawdust, straw, farm waste and so on.

Granular Shape: Cylinder

Granulation Rate: 100%

This production line is mainly used for (bio) organic fertilizer and pellet processing in the aquaculture processing industry. There is no need to dry and pulverize the raw materials before granulation, and the cylindrical granules can be directly batched and processed, which saves a lot of energy. The surface of the granular material processed by this machine is smooth and clean, with moderate hardness, low temperature rise during processing and good maintenance of various nutrients inside the raw material; the diameter of the particle size can be divided into: Φ2, Φ2.5, Φ3.5, Φ4, Φ5, Φ6, Φ7, Φ8, etc. Users can choose according to production needs when ordering.

Equipments of flat die granulator fertilizer production line:

| Crushing machine | Mainly used for the crushing of raw materials to meet the requirements of granulation. |

| Mixing machine | It is used for mixing and stirring materials, adjusting the moisture content of materials, adding trace elements to meet the needs of granulation. |

| Flat die granulator | for making the fertilizer granules. |

| Throw round shaping machine | The machine is mainly used in conjunction with the granulator to increase the granulation output and achieve smooth and bright appearance of the granules. |

| Rotary dryer | It is mainly used for drying after granulation, so that the granules can quickly reduce the moisture at high temperature, which is convenient for storage and achieves continuous and uninterrupted production. |

| Cooling machine | It is mainly used to cool down and remove moisture after drying, so that the material can quickly reach normal temperature, meet the storage requirements, and realize continuous and uninterrupted production. |

| Screener machine | Wear-resistant steel mesh. It is mainly used for the separation of finished products and returned materials, and can also realize the classification of finished products, so that the finished products can be evenly classified. |

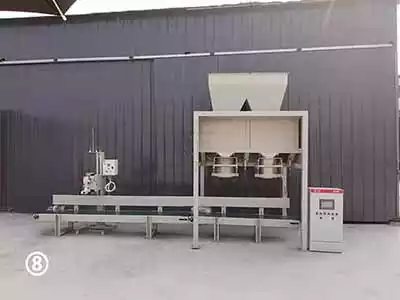

| Package machine | It is mainly composed of main machine, machine column, sewing machine head and conveyor belt. Different specifications can be packaged to improve work efficiency and reduce operating costs. |

Organic fertilizer production line with flat die extrusion granulator:

Package : wooden package or full 20GP/40HQ container

Create a simple and convenient service experience for you anytime, anywhere.